SBVC Innovates Curriculum with New Simulation Software

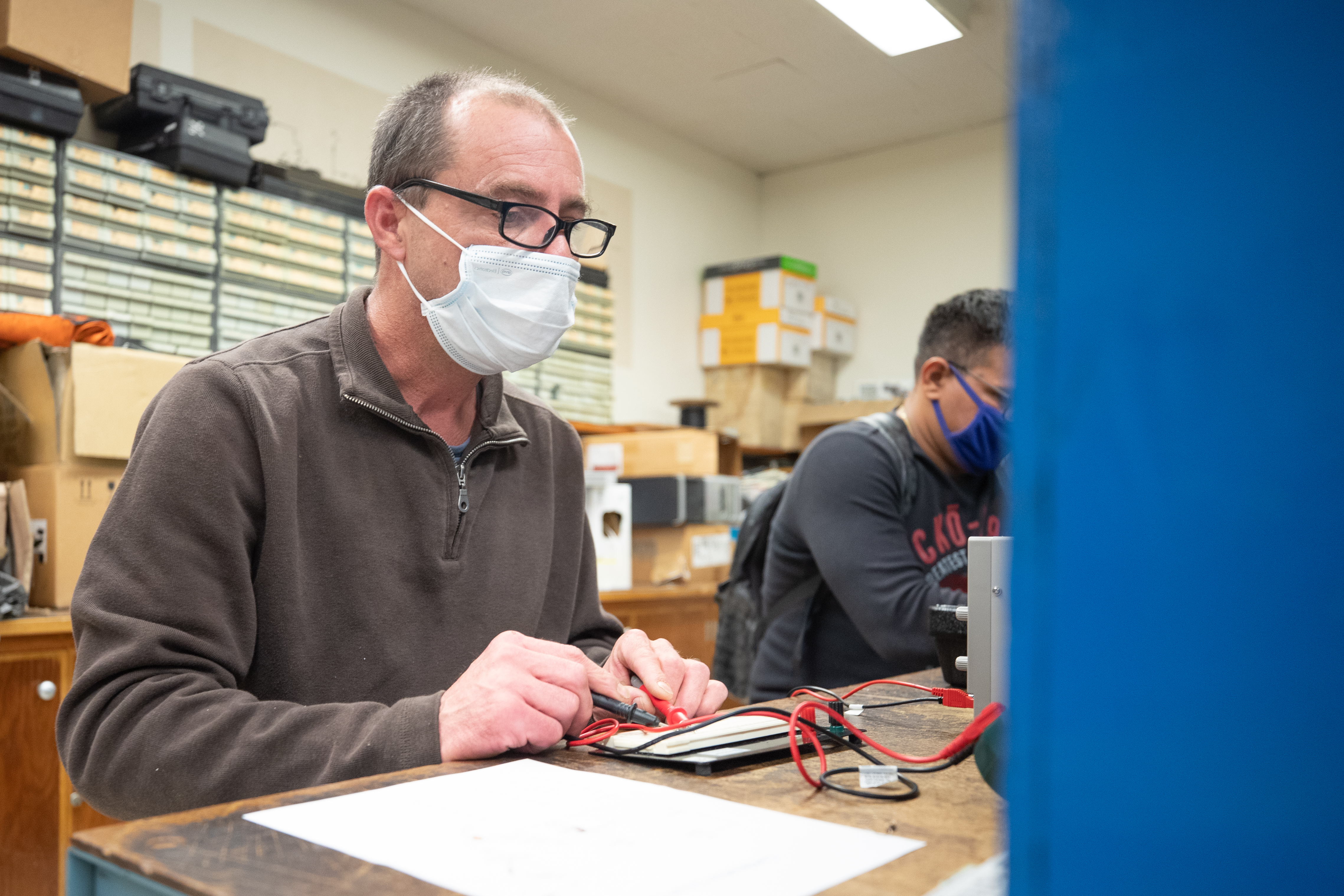

SBVC had to adapt most of its hands-on courses during the recent pandemic and campus shutdown. However, its Electricity/Electronics Technology department were able to innovate its teaching of critical industrial automation skills to keep conveyor belts moving. Last year, SBVC shifted to industrial automation simulators in mechatronics courses to overcome training disruptions arising from the pivot to online learning. The bold move meant students could keep up with their studies and continue landing above-entry-level careers in the industry.

During this virtual shift, SBVC began using cutting-edge simulation software by LabVolt. “LabVolt is a huge trainer manufacturing company for educational systems, which basically simulate everything that’s out in industry,” explained department chair Tarif Halabi. “They basically simulated [the equipment] so well that you could do 85 percent of the class without having the system there.”

The simulation trainers present the same small-scale systems that Amazon and other

industry giants use in their warehousing and distribution centers. Automated systems

save companies a tremendous amount of time as items are imaged, sorted, measured,

and recorded at lightning speed.  SBVC students learn the core skills to help manufacturers mass-produce and distribute,

allowing them to save on labor costs and operate more efficiently. From barcode readers

to temperature modulators, the school’s new software emulated the same industrial

controls for pneumatics, fluid hydraulics and sensors.

SBVC students learn the core skills to help manufacturers mass-produce and distribute,

allowing them to save on labor costs and operate more efficiently. From barcode readers

to temperature modulators, the school’s new software emulated the same industrial

controls for pneumatics, fluid hydraulics and sensors.

As a result, at least four students recently graduated in a virtual environment and became Electronic Systems Technician Level 2 with Amazon, joining three other alums already working on such systems. According to department chair Tarif Halabi, Tech 2 employees earn $25 an hour with full benefits, with paychecks increasing to $33 an hour when they progress to Tech 3. In fact, the simulation trainers were so successful that the College continues to include the virtual tech even after classes returned to campus.

Students are also hired far and wide in the region, including the mega Walmart distribution center in Colton that opened in 2019. “I had two students who placed with them because they all use the same type of automation shelving and distribution system for logistics,” said Halabi. The Inland Empire has increasingly become the epicenter for logistics and transportation ware-houses. In 2019, the region housed 21 of the nation’s 100 biggest logistics leases, comprising 17.5 million square feet, according to the California attorney general’s office.

Meanwhile, the need for warehouses and workers has only increased since the pandemic, as demand for online shopping, and the warehouses to store those goods, continues to grow. Currently, there are more than 700 big-box warehouses in Inland Empire, with more on the way.