Welding Technology

The Welding Technology program prepares students for employment in welding occupations and occupations where welding is required. Our program provides students with an understanding of the welding industry’s requirements for employment and helps them to acquire entry-level job skills. Hands-on experience is emphasized in addition to a strong background in theory. Courses are held in well-equipped welding labs. Upon successful completion of the program, students will be able to demonstrate industry accepted welding and fabrication skills including, but not limited to: SMAW, FCAW, GMAW, GTAW, OAW and OFC in all positions with a variety of metals and alloys. Students are given opportunities to test and achieve certifications in welding that are included in the courses at no additional cost to enrolled students. The program also offers classes to prepare students to become Certified Welding Inspectors and L.A. City Certified Welders.

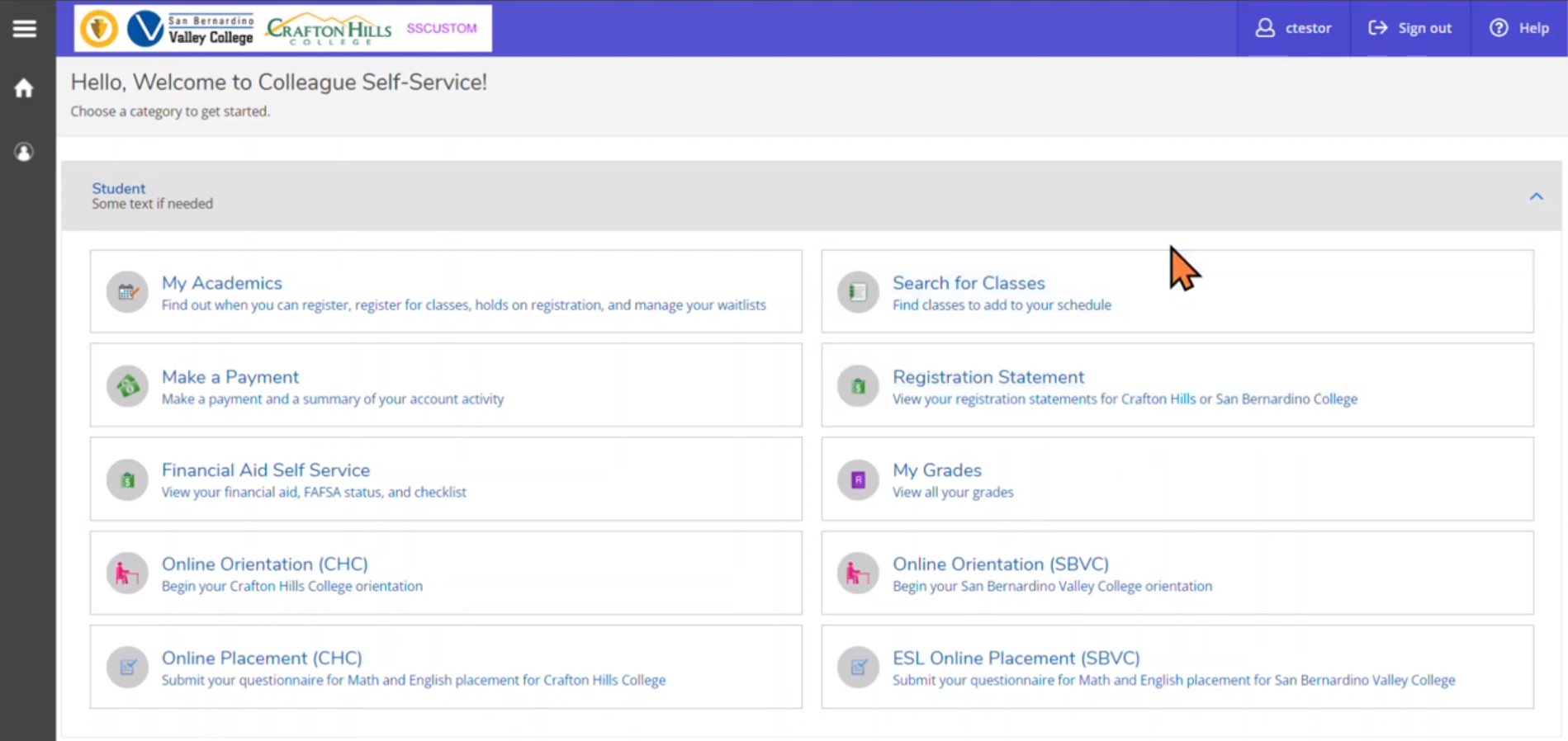

Degrees & Certificates

-

Flux Cored Arc Welding (FCAW) COA

-

Gas Metal Arc Welding (GMAW) COA

-

Gas Tungsten Arc Welding (GTAW) COA

-

Pipe Welding COA

-

Shielded Metal Arc Welding (SMAW) COA

-

Welding Inspection Technology COA

-

Welding Job Readiness COC

-

Welding Technology AS

-

Welding Technology COA